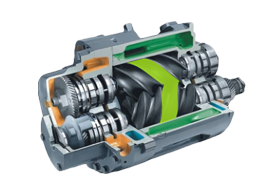

Working principle of screw compressor

In oil-free screw compressors, the gas does not contact the lubricating oil during compression. The rotors of oil-free compressors do not directly contact, and there is a certain gap between them. The male rotor drives the female rotor through synchronous gear

The high-speed rotation of the sub-synchronous gears ensures the clearance between the rotors while transmitting power. The so-called "oil-free" of oil-free screw compressors means that the gas is not in contact with oil at all during compression, that is, there is no oil lubrication between the compressor's compression chamber or rotor. However, the bearings, gears and other components in the compressor are still lubricated by ordinary lubrication methods, only between these lubrication parts and the compression cavity,

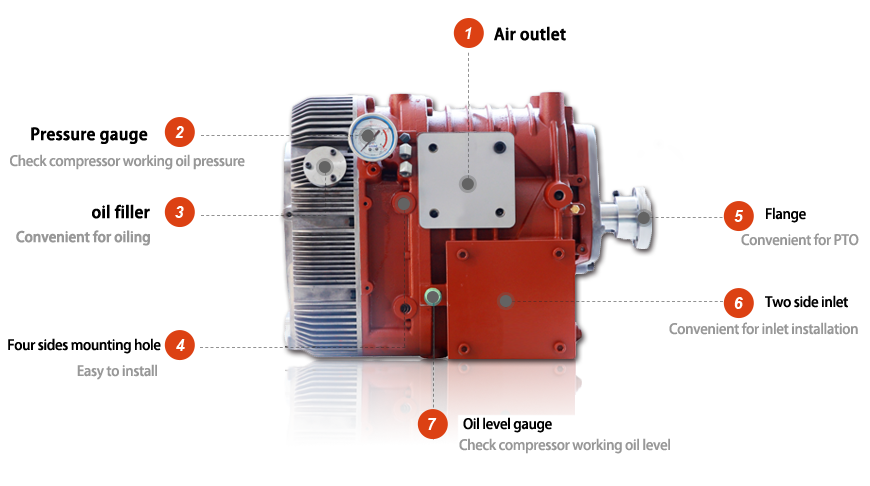

Adopt effective isolation shaft seal. The main structure of the oil-free screw compressor is relatively complicated. The main body is mainly composed of the male and female rotors, the body and the end cover on the exhaust side, the front body,

The back cover, synchronous gear, bearing, bearing seat, shaft seal, balance piston and other components.

-

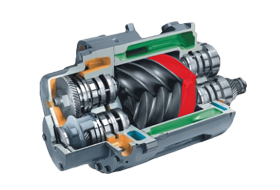

Intake

The volume between the teeth of the Mingyang rotor gradually expands with the rotation of the rotor, when the volume reaches the maximum. The volume between the teeth is disconnected from the air hole, and Wanwei breathes in

-

Start compression

The rotor continues to rotate, and the volume of the yin and yang rotor teeth is connected

-

exhaust

The compressed air reaches the rated pressure, at this time the volume between the teeth and the vent hole are conceived to eliminate the gas

WeChat

WeChat